Equipment introduction

Raymond Strip Continuous Plating Equipment Line - High-Precision Metal Strip Plating

Raymond Strip Continuous Plating Equipment Line

High-Precision Metal Strip Plating · Superior Uniformity · Enhanced Efficiency

Product Introduction

The Raymond Strip Continuous Plating Equipment Line is a highly specialized and automated solution designed for the efficient and precise electroplating of metal strips, coils, and wires. This advanced system is crucial for industries requiring uniform and high-quality surface finishes on continuous materials, such as electronics, automotive, construction, and decorative applications. Unlike batch plating, continuous strip plating offers significant advantages over traditional batch processing, including higher consistency, higher production speeds, and reduced material handling, making it ideal for high-volume manufacturing of components like connectors, lead frames, busbars, and decorative trims.

At Raymond, we leverage decades of expertise and global best practices from leading manufacturers in Europe, USA, Japan, and Korea to deliver cutting-edge continuous strip plating solutions. Our equipment integrates sophisticated material handling, precise chemical management, and advanced process control systems to ensure optimal performance and reliability. We focus on delivering lines that provide exceptional coating uniformity, excellent adhesion, and minimal material waste, while also adhering to stringent environmental standards. Partner with Raymond for a robust and efficient continuous strip plating solution that enhances your product quality, optimizes production efficiency, and provides a competitive edge in the global market.

Core Advantages of Raymond Strip Continuous Plating Equipment Lines

- High Production Efficiency: Designed for continuous, high-speed operation, significantly increasing throughput and reducing processing time compared to traditional batch methods.

- Superior Coating Uniformity: Ensures consistent plating thickness and quality across the entire length and width of the strip, crucial for precision components.

- Reduced Material Handling: Automated unwinding, processing, and rewinding minimize manual intervention, leading to lower labor costs and reduced risk of material damage.

- Precise Process Control: Advanced PLC and HMI systems allow for real-time monitoring and precise control of plating parameters, including current density, temperature, and chemical composition.

- Versatile Application: Capable of plating various metals (e.g., gold, silver, nickel, tin, copper) onto different strip materials (e.g., steel, copper alloys, brass) for diverse industrial needs.

- Selective Plating Capabilities: Our lines can be configured for selective plating, allowing specific areas of the strip to be plated while others remain untouched, saving precious metal costs.

- Enhanced Adhesion & Durability: Optimized pre-treatment and plating processes ensure strong adhesion of the metallic layer, providing long-lasting performance and corrosion resistance.

- Environmental Responsibility: Integrated chemical recovery, wastewater treatment, and fume extraction systems minimize environmental impact and ensure compliance with regulations.

Process Flow

The Raymond Strip Continuous Plating Equipment Line follows a meticulously engineered multi-stage process to ensure high-quality and consistent plating on continuous metal strips.

1

Unwinding & Pre-treatment

The metal strip coil is unwound and fed into the line. It undergoes a series of cleaning and activation steps, including degreasing, rinsing, and acid pickling, to prepare the surface for optimal plating adhesion.

2

Electroplating Sections

The strip passes through multiple plating cells, where the desired metal is electrodeposited onto its surface. Each cell is precisely controlled for current density, electrolyte composition, and temperature to achieve uniform coating thickness and quality. Selective plating can be performed in specific zones.

3

Multi-Stage Rinsing & Post-treatment

After plating, the strip undergoes thorough multi-stage rinsing to remove residual chemicals. Depending on the application, post-treatment processes like passivation, drying, or anti-tarnish treatments may be applied.

4

Drying & Rewinding

The processed strip is then dried using hot air or infrared systems and precisely rewound onto a finished coil, ready for subsequent manufacturing steps or direct use.

Technical Specifications

Raymond Strip Continuous Plating Equipment Lines are engineered for superior performance, reliability, and adaptability, incorporating advanced features inspired by global industry leaders.

| Technical Parameter |

Specification Range |

| Line Type |

Fully Automatic Strip/Coil Continuous Electroplating Line |

| Strip Width |

10mm - 500mm (customizable) |

| Strip Thickness |

0.05mm - 2.0mm (customizable) |

| Operating Speed |

1 - 50 m/min (adjustable based on plating thickness and material) |

| Plating Metals |

Gold, Silver, Nickel, Tin, Copper, Zinc, Palladium, Rhodium (customizable) |

| Substrate Materials |

Copper alloys, Brass, Steel, Stainless Steel, Kovar, etc. |

| Coating Thickness |

0.1 µm - 20 µm (adjustable based on application requirements) |

| Control System |

Advanced PLC Control (Siemens, Mitsubishi), HMI Touchscreen, SCADA Integration, Data Logging |

| Rectifiers |

High-frequency switching rectifiers with precise current/voltage control |

| Chemical Management |

Automated dosing, filtration, circulation, and analysis systems |

| Environmental Systems |

Fume extraction, wastewater treatment, metal recovery, air purification |

| Safety Features |

Emergency stop, interlocks, leak detection, fire suppression, ventilation |

| Automation Level |

Fully Automated Unwinding, Plating, Rinsing, Drying, Rewinding |

Solving Customer Pain Points

The Raymond Strip Continuous Plating Equipment Line is designed to effectively address critical challenges faced by manufacturers requiring high-quality, high-volume plating on continuous metal strips.

Challenge: Inconsistent Plating Quality on Long Strips

Our Solution: Our precise tension control, optimized plating cell design, and real-time parameter monitoring ensure uniform coating thickness and composition across the entire length of the strip, eliminating quality variations.

Challenge: High Production Costs & Low Throughput with Batch Plating

Our Solution: Continuous processing significantly increases production speed and efficiency, reducing labor costs, chemical consumption, and overall manufacturing expenses compared to traditional batch methods.

Challenge: Wasteful Use of Precious Metals in Overall Plating

Our Solution: Our advanced selective plating capabilities allow for precise deposition of precious metals only on required areas, dramatically reducing material costs and improving cost-effectiveness.

Challenge: Complex Material Handling & Potential for Damage

Our Solution: Fully automated unwinding, feeding, and rewinding systems minimize manual handling, preventing damage to delicate strips and ensuring smooth, uninterrupted production.

Challenge: Meeting Stringent Quality & Performance Standards

Our Solution: Our equipment is engineered to meet the highest industry standards for adhesion, corrosion resistance, electrical conductivity, and appearance, crucial for high-performance applications.

Challenge: Environmental Compliance & Waste Management

Our Solution: Integrated chemical recovery, wastewater treatment, and air purification systems ensure compliance with environmental regulations, reduce waste, and promote sustainable manufacturing practices.

Related Keywords: strip continuous plating, continuous strip plating equipment, metal strip electroplating, coil plating line, high-speed plating, selective plating, Raymond plating solutions, industrial strip plating, continuous metal finishing, automated strip plating.

Continuous plating is a process of electroplating on the surface of a continuous strip and is typically used in industries that produce large quantities of metal products. The technology is more productive than traditional plating methods and enables rapid processing of large quantities.

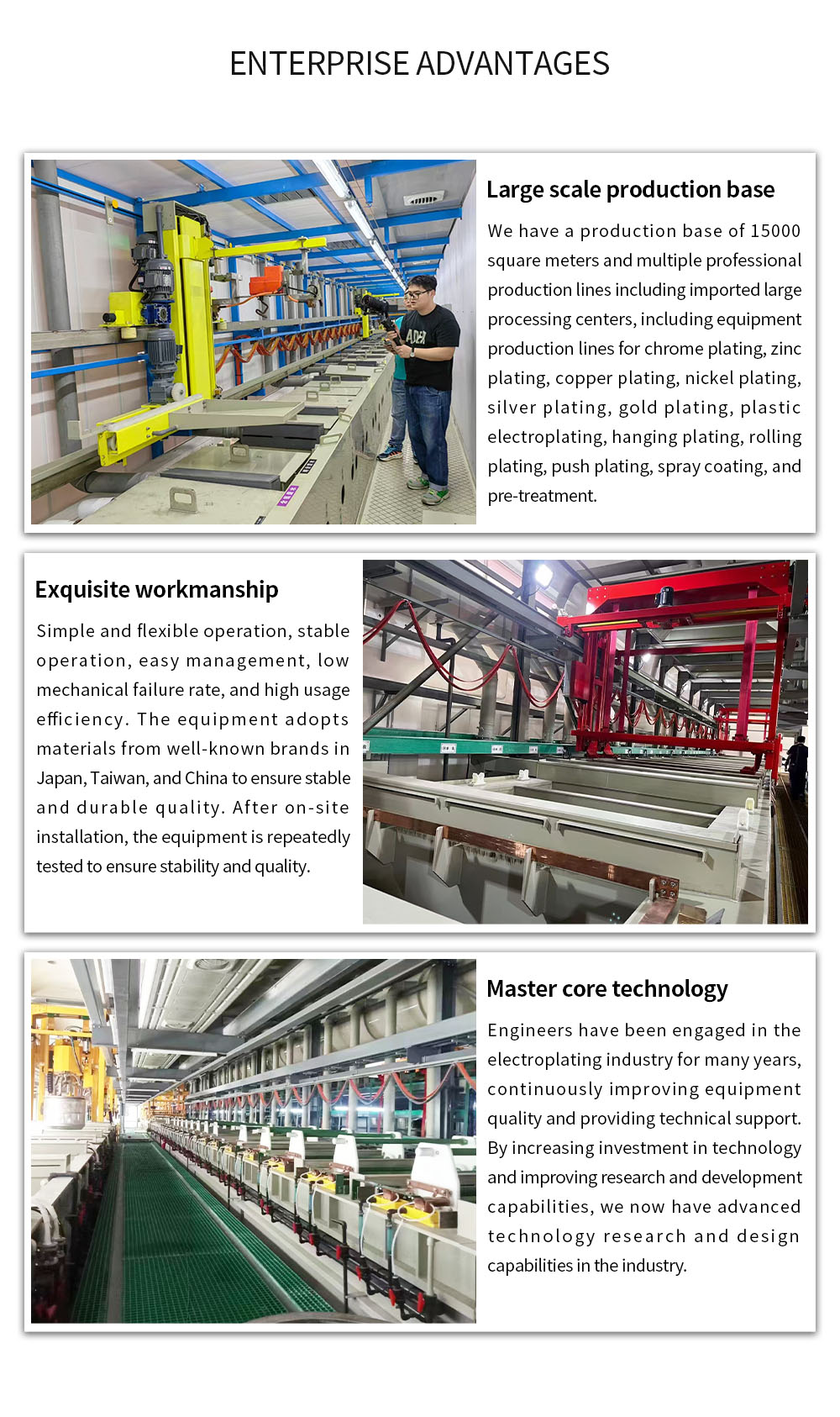

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

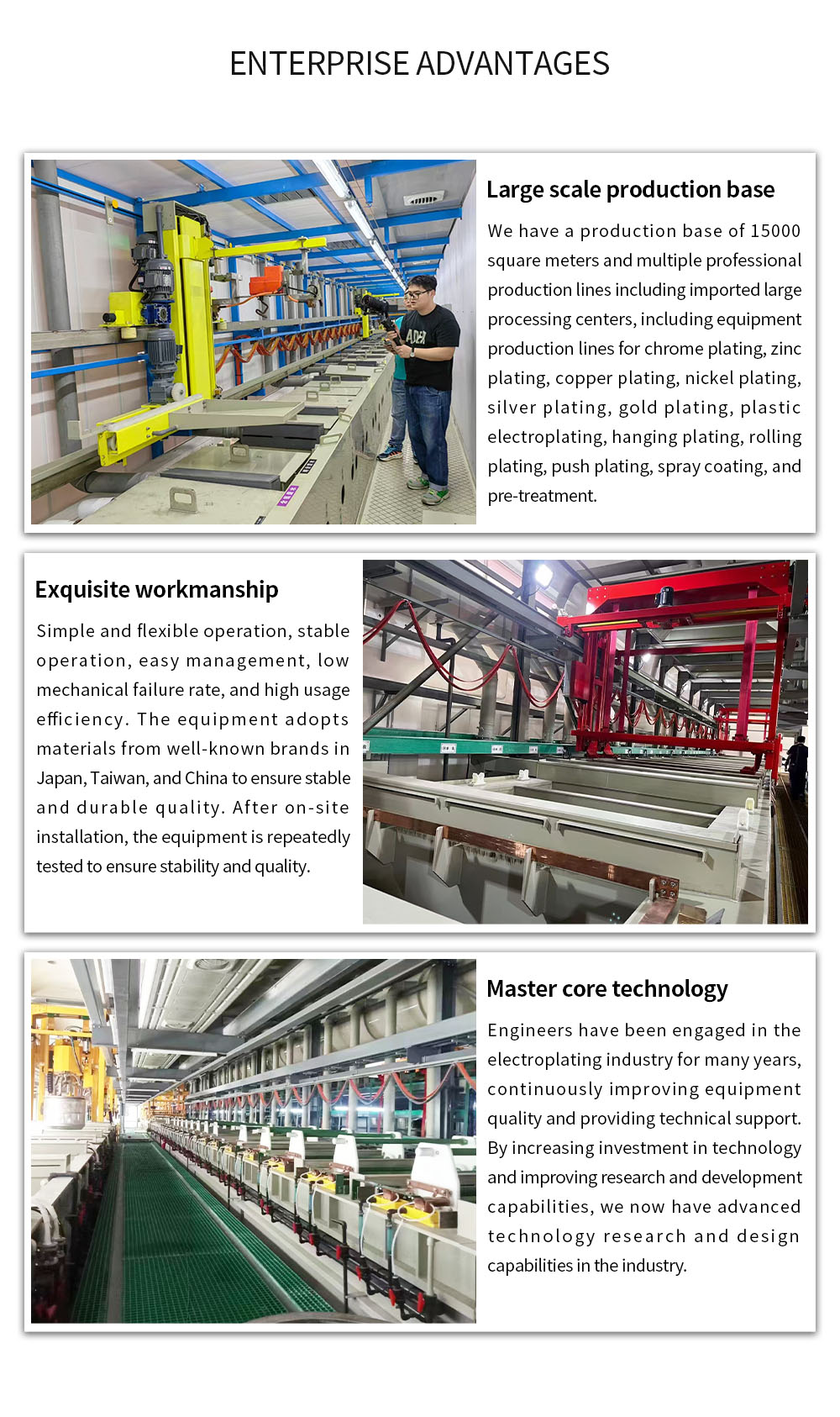

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.