Suspension Conveyor,Suspension Conveyor manufacturer

Company:

Raymond (Changzhou) Equipment Co., Ltd. | Plating Automation Solution Provider

Keywords:

Suspension Conveyor,Suspension Conveyor manufacturer

Raymond (Changzhou) Equipment Co., Ltd. | Plating Automation Solution Provider

Suspension Conveyor,Suspension Conveyor manufacturer

Material Handling Solutions · Efficient Transportation · Advanced Automation

The Raymond Suspension Conveyor is a versatile and efficient material handling solution designed for the continuous transportation of products through various manufacturing processes. This advanced overhead conveyor system utilizes suspended carriers to move parts along predetermined paths, providing optimal space utilization and seamless integration with production lines. Our suspension conveyor is essential for automotive assembly, appliance manufacturing, surface treatment operations, and general industrial applications where efficient, automated material handling is critical for maintaining production flow and maximizing operational efficiency.

At Raymond, we integrate global best practices and innovative technologies from leading manufacturers in Europe, USA, Japan, and Korea to deliver superior suspension conveyor solutions. Our equipment is engineered for optimal performance, reliability, and flexibility, featuring robust construction, precise speed control, and advanced automation capabilities. We focus on providing systems that not only enhance material handling efficiency but also reduce labor costs, minimize product damage, and ensure seamless integration with existing production processes. Partner with Raymond for a robust and efficient suspension conveyor solution that optimizes your material flow and strengthens your competitive position in automated manufacturing.

The Raymond Suspension Conveyor system consists of several key components working together to provide efficient material handling solutions.

Heavy-duty steel track provides the structural foundation for the conveyor system, supporting carriers and loads throughout the transportation path.

Powerful drive motors and gearboxes provide the motive force for the conveyor system, with variable speed control for optimal operation.

Specialized carriers and trolleys transport products along the track system, with customizable fixtures for various part types and sizes.

Automated or manual loading and unloading stations facilitate efficient product transfer to and from the conveyor system.

Advanced PLC-based control systems manage conveyor operation, tracking, routing, and integration with other production equipment.

Comprehensive safety features including emergency stops, guards, and monitoring systems ensure safe operation and personnel protection.

Raymond Suspension Conveyor systems are engineered for superior performance, reliability, and flexibility, incorporating advanced features inspired by global industry leaders.

| Technical Parameter | Specification Range |

|---|---|

| System Type | Overhead Suspension Conveyor System |

| Track Length | 50 - 5000 meters (customizable) |

| Load Capacity | 50 - 2000 kg per carrier |

| Conveyor Speed | 1 - 30 meters/minute (variable) |

| Track Profile | I-beam, C-channel, or custom profiles |

| Carrier Spacing | 1 - 10 meters (adjustable) |

| Vertical Clearance | 3 - 12 meters (customizable) |

| Horizontal Curves | Minimum radius 1.5 - 5 meters |

| Vertical Curves | Inclines up to 30 degrees |

| Drive System | Electric motors with variable frequency drives (VFD) |

| Control System | PLC Control (Siemens, Allen-Bradley), HMI Interface, SCADA Integration |

| Tracking System | RFID, barcode, or proximity sensors for carrier identification |

| Material | Carbon steel, stainless steel, or aluminum construction |

| Environmental Rating | Standard, wash-down, or explosion-proof configurations |

| Safety Features | Emergency stops, safety guards, overload protection, collision avoidance |

| Integration | Compatible with ERP, MES, and other production management systems |

The Raymond Suspension Conveyor is designed to effectively address critical challenges faced by manufacturers requiring efficient material handling solutions.

Our Solution: Overhead suspension design maximizes floor space utilization and provides flexible routing options to optimize plant layout and workflow efficiency.

Our Solution: Automated conveyor system eliminates manual material handling, reduces labor requirements, and minimizes the risk of product damage and worker injury.

Our Solution: Continuous material flow and buffer capacity eliminate bottlenecks and maintain consistent production flow throughout the manufacturing process.

Our Solution: Flexible track configuration and advanced routing capabilities accommodate complex layouts, multiple levels, and diverse transportation requirements.

Our Solution: Advanced control systems and standardized interfaces ensure seamless integration with existing production equipment and management systems.

Our Solution: Robust construction, quality components, and predictive maintenance capabilities minimize downtime and reduce overall maintenance costs.

Suspended conveyor chain continuously carries goods along the same route according to a fixed line. It can be used to carry goods within the workshop or between workshop and workshop, and at the same time, it can carry out certain process operations in the process of carrying. Such as paint dipping, drying, heat preservation, cooling, assembly and other industrial operations. Reasonable line design can be carried out according to the different process requirements of users, so that the conveyed objects can be handled with special processes, such as powder spraying, painting, galvanizing, drying, etc., at an ideal speed.

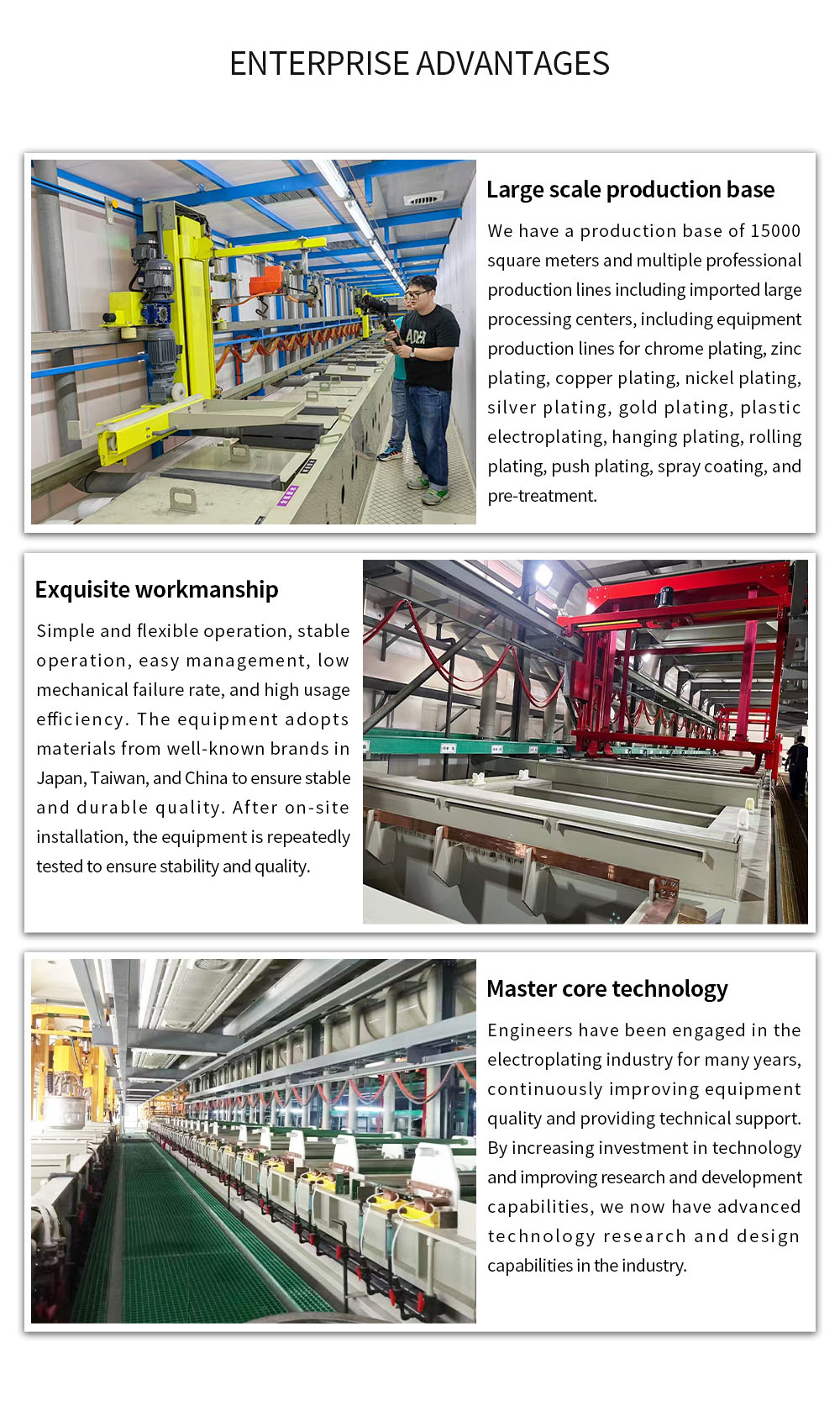

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.