Roller Plating Silver Equipment Line,Roller Plating Silver Equipment Mnaufacturer

Company:

Raymond (Changzhou) Equipment Co., Ltd. | Plating Automation Solution Provider

Keywords:

Plating Silver Equipment Line,Plating Silver Equipment Manufacturer

Raymond (Changzhou) Equipment Co., Ltd. | Plating Automation Solution Provider

Plating Silver Equipment Line,Plating Silver Equipment Manufacturer

High Conductivity & Aesthetic Finish for Small Components

The Raymond Roller Plating Silver Equipment Production Line offers a sophisticated and highly efficient solution for applying high-quality silver coatings to a wide range of small to medium-sized components. Silver plating is renowned for its excellent electrical conductivity, superior solderability, good lubricity, and attractive aesthetic appeal, making it indispensable in industries such as electronics, automotive, jewelry, and medical devices. Our production lines are specifically designed for the mass processing of parts using the barrel (roller) plating method, ensuring uniform deposition and consistent quality even on complex geometries.

At Raymond, we engineer our silver plating lines with precision and advanced technology, incorporating automated systems for precise chemical control, temperature management, and material handling. We focus on delivering solutions that maximize plating efficiency, minimize silver consumption, and adhere to stringent environmental regulations. Drawing on best practices from leading manufacturers in Europe, USA, Japan, and Korea, our lines are built for reliability, high throughput, and exceptional finish quality. Partner with Raymond for a state-of-the-art silver plating solution that enhances your product's performance, extends its lifespan, and meets the highest industry standards.

The Raymond Roller Plating Silver Equipment Production Line follows a precise and carefully controlled sequence of steps to ensure the efficient and high-quality deposition of silver onto small components. The process is designed for optimal adhesion, uniformity, and performance.

Parts are thoroughly cleaned to remove oils, grease, oxides, and other contaminants. This typically involves alkaline cleaning, rinsing, and acid activation. A perfectly clean and active surface is essential for proper silver adhesion and a defect-free finish.

For many applications, especially on ferrous metals or copper alloys, a thin nickel undercoat is applied. This layer improves adhesion, enhances corrosion resistance, and prevents migration of base metals into the silver layer.

Cleaned and pre-treated parts are loaded into perforated plating barrels, which are then immersed in the silver plating bath. A rectifier supplies direct current, causing silver ions to deposit onto the parts as they continuously tumble within the rotating barrel. This ensures even and consistent silver deposition.

After achieving the desired silver thickness, the barrels move through multiple rinsing stages to thoroughly remove any residual plating solution, preventing contamination and ensuring cleanliness.

Silver is prone to tarnishing when exposed to sulfur-containing compounds in the atmosphere. A post-treatment anti-tarnish dip is applied to protect the silver surface and maintain its bright appearance and conductivity over time.

Finally, the parts are dried using centrifugal dryers or hot air blowers. Once dry, the barrels are automatically unloaded, and the finished silver-plated parts are ready for inspection or further processing.

Raymond Roller Plating Silver Equipment Production Lines are engineered for superior performance, reliability, and adaptability, incorporating advanced features inspired by global industry leaders.

| Technical Parameter | Specification Range |

|---|---|

| Production Line Type | Fully Automatic Barrel (Roller) Plating Line |

| Control System | PLC Control (e.g., Siemens, Mitsubishi), HMI Touchscreen, SCADA Integration |

| Plating Process | Bright Silver Plating, Matte Silver Plating |

| Applicable Parts | Electrical Contacts, Connectors, Fasteners, Jewelry Components, Medical Devices, etc. |

| Barrel Material | PP (Polypropylene), PVC (Polyvinyl Chloride), PVDF (Polyvinylidene Fluoride) |

| Barrel Size | Customizable, typically 10-80 Liters capacity |

| Production Capacity | High volume, e.g., 300-1500 kg/hour (depending on part size and process) |

| Rectifier Type | High-Frequency Switching Power Supply |

| Current Density | Adjustable, optimized for specific silver plating baths |

| Temperature Control | ±1 °C Precision for plating baths |

| Chemical Dosing | Automated Dosing Pumps for Solution Maintenance |

| Filtration System | Continuous Filtration for plating baths |

| Environmental Controls | Fume Extraction & Scrubbers, Wastewater Treatment Options, Silver Recovery Systems |

| Safety Features | Emergency Stop, Overload Protection, Safety Interlocks, Ventilation Systems |

The Raymond Roller Plating Silver Equipment Production Line is designed to effectively address critical challenges faced by manufacturers requiring high-quality silver plating, ensuring superior performance and operational efficiency.

Our Solution: Our automated lines provide precise control over all plating parameters, ensuring uniform silver deposition and a consistent, bright, or matte finish across every part, minimizing defects and rework.

Our Solution: We integrate advanced anti-tarnish post-treatment stages into our lines. This significantly protects the silver surface from oxidation and sulfur-induced tarnishing, maintaining its conductivity and aesthetic appeal over time.

Our Solution: Our optimized bath designs and efficient rinsing and recovery systems are engineered to minimize drag-out and silver loss, leading to reduced silver consumption and lower operational costs, making silver plating more economically viable.

Our Solution: Our precise process control ensures the deposition of high-purity silver layers with excellent electrical conductivity and superior solderability, critical for high-performance electronic and electrical components.

Our Solution: The roller (barrel) plating method is inherently efficient for mass production. Our automated lines further enhance this efficiency, allowing for high throughput and reduced labor costs for small components.

Our Solution: We design our silver plating lines with integrated environmental controls, including fume extraction, wastewater treatment, and silver recovery systems, ensuring compliance with strict environmental regulations and promoting sustainable manufacturing practices.

Roller plating silver plating equipment production line is a kind of production line specialized in silver plating process, which covers the silver layer on the surface of the workpiece uniformly by roller plating. This kind of production line has the advantages of high efficiency, uniformity and high degree of automation, which is widely used in electronics, hardware, decoration and other industries.

I. Main Components of Silver Plating Production Line

The production line of silver plating equipment usually consists of pre-treatment equipment, roller plating tank, post-treatment equipment, control system and auxiliary equipment.

1. Pre-treatment equipment: It is used for cleaning, degreasing, descaling and other pre-treatment of the workpiece to ensure the quality of the plating layer. 2.

2. Plating tank: It is the core equipment of silver plating process, which contains silver plating solution and roller. The workpiece rolls in the drum with the rotation of the drum, and comes into full contact with the silver plating solution, thus realizing silver plating.

3. After-treatment equipment: Used for cleaning and drying the silver-plated workpiece to remove excess plating solution and water.

4. Control system: It is used to monitor and adjust the operation of the whole production line to ensure the stability of the production process and product quality.

5. Auxiliary equipment: such as lifting equipment, conveyor belts, etc., for handling and transporting workpieces.

II. Process flow of silver plating equipment production line

The process of silver plating equipment production line generally includes the following steps:

1. Pre-treatment: Pre-treatment of the workpiece, such as cleaning, degreasing, descaling, etc., to ensure that the surface of the workpiece is clean and free of impurities.

2. Basket loading: Loading the pre-treated workpieces into the basket specially designed for barrel plating to tumble in the barrel plating tank.

3. Tumbling: put the basket with the workpiece into the tumbling tank, through the rotation of the drum to make the workpiece and the silver plating solution fully contact to realize the silver plating.

4. Reworking: The silver-plated workpieces are cleaned and dried to remove excess plating solution and water.

5. Inspection: Perform quality inspection on the silver-plated parts to ensure that the plating layer is uniform, smooth and free of defects.

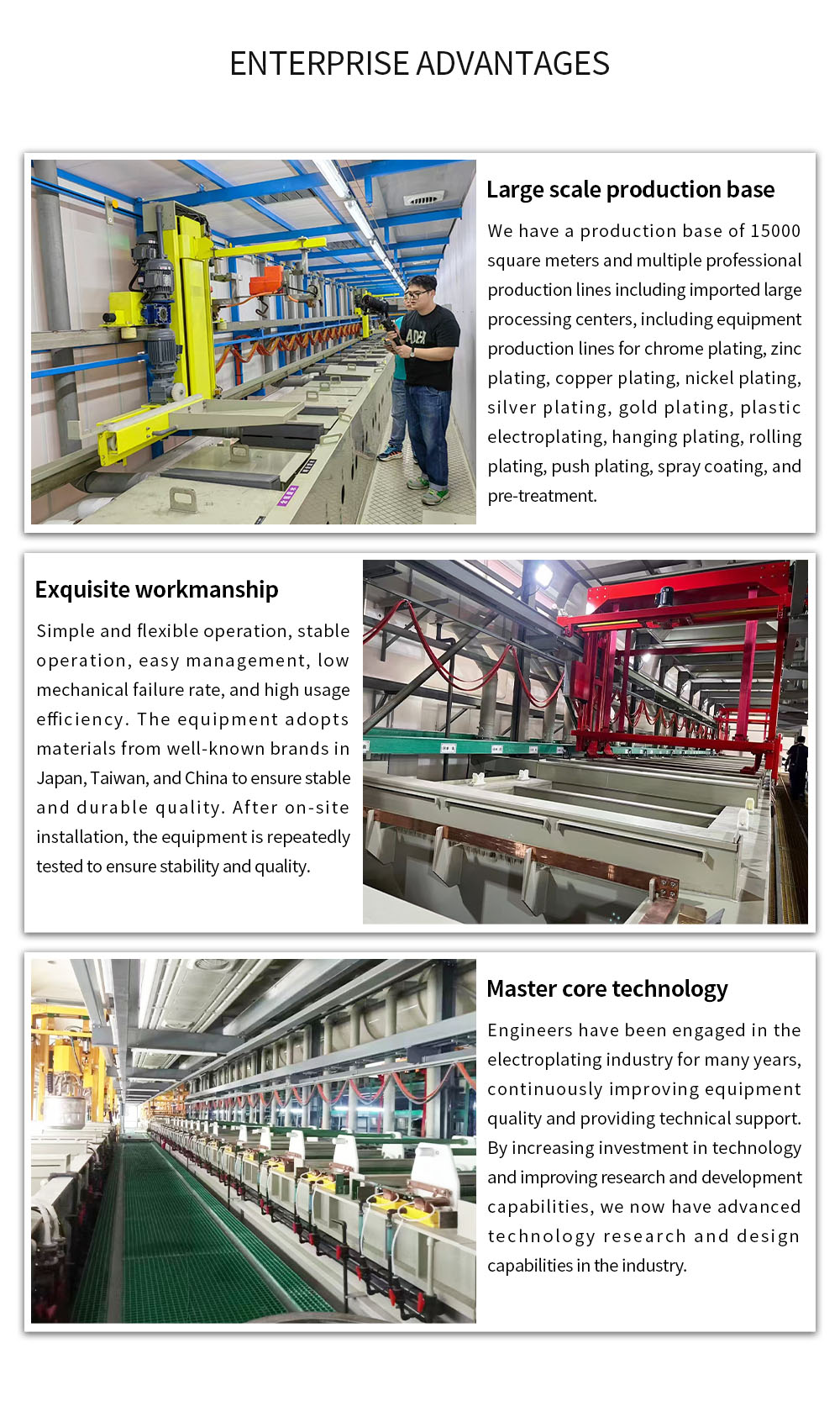

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.