Equipment introduction

Raymond Electrophoresis Automatic Equipment Production Line - Advanced E-Coating Solutions

Raymond Electrophoresis Automatic Equipment Production Line

Advanced E-Coating Solutions · Superior Corrosion Protection · High Efficiency & Automation

Product Introduction

The Raymond Electrophoresis Automatic Equipment Production Line is a cutting-edge solution for industrial surface finishing, specifically designed for high-volume, high-quality electrophoretic coating (E-coating). This advanced system leverages the principles of electrodeposition to apply uniform, durable, and corrosion-resistant coatings to a wide array of metallic and conductive substrates. Widely adopted in the automotive, appliance, and general industrial sectors, our E-coating lines provide superior protection and aesthetic appeal, significantly extending the lifespan of finished products.

At Raymond, we understand the critical importance of robust corrosion protection and efficient production. Our automated electrophoresis lines are meticulously engineered to deliver consistent, high-performance results while optimizing resource utilization. Featuring state-of-the-art automation, precise process control, and integrated environmental management systems, our lines minimize material waste, reduce energy consumption, and ensure compliance with stringent environmental regulations. From initial pre-treatment to final curing, the Raymond E-coating line offers a comprehensive, integrated solution that enhances product quality, streamlines manufacturing processes, and drives down operational costs, empowering your business to achieve unparalleled finishing excellence.

Core Advantages of Raymond Electrophoresis Automatic Equipment Production Lines

- Exceptional Corrosion Resistance: Electrophoretic coatings provide a dense, uniform barrier that offers superior protection against rust, chemicals, and environmental degradation, significantly extending the service life of components, especially in harsh conditions.

- Unmatched Coating Uniformity: The electrodeposition process ensures an incredibly even coating thickness across complex geometries, including recessed areas, sharp edges, and internal surfaces, eliminating common issues like runs, sags, and bare spots found in traditional painting methods.

- High Transfer Efficiency & Material Utilization: With transfer efficiencies often exceeding 95%, E-coating minimizes paint waste. Our lines incorporate advanced ultrafiltration and recycling systems to recover unused paint, leading to significant material cost savings and reduced waste disposal.

- Fully Automated & High Throughput: Designed for continuous, high-volume production, our lines feature intelligent automation, robotic handling, and optimized process sequences. This translates to reduced labor costs, increased production speed, and consistent output, meeting the demands of modern manufacturing.

- Environmentally Friendly Operation: Utilizing water-based paints with low VOC (Volatile Organic Compound) content, combined with closed-loop rinsing, wastewater treatment, and fume extraction systems, our E-coating lines are highly compliant with global environmental standards, promoting sustainable manufacturing practices.

- Versatile Application: Capable of coating a wide range of conductive materials and compatible with various types of E-coat paints (e.g., cathodic epoxy, acrylic), making it suitable for diverse applications from automotive parts and consumer electronics to industrial machinery.

- Enhanced Safety: The enclosed nature of the E-coating process, combined with automated chemical handling and ventilation systems, significantly reduces operator exposure to hazardous materials, creating a safer working environment.

Process Flow

The Raymond Electrophoresis Automatic Equipment Production Line follows a precise, multi-stage process to ensure optimal coating quality and performance.

1

Pre-treatment

Workpieces undergo a series of cleaning and surface preparation steps, typically including degreasing, rinsing, and phosphating (or other conversion coatings). This crucial stage ensures a clean, active, and receptive surface for optimal paint adhesion and corrosion performance.

2

Electrophoretic Deposition (E-coating)

Parts are immersed in a tank containing the E-coat paint bath. An electric current is applied, causing the paint particles to migrate and deposit uniformly onto the conductive workpiece. Parameters such as voltage, current, immersion time, and bath temperature are precisely controlled.

3

Ultrafiltration Rinsing

After deposition, parts pass through multiple rinse stages using ultrafiltrate (UF) from the paint bath. This recovers excess paint solids, preventing drag-out and ensuring a clean, smooth surface before curing. The UF system also helps maintain bath purity.

4

Curing Oven

The coated parts are then transported into a high-temperature curing oven. Here, the paint film is cross-linked and polymerized, transforming it into a hard, durable, and corrosion-resistant finish. Oven temperature and dwell time are critical for achieving desired coating properties.

5

Cooling & Inspection

Finally, the cured parts are cooled and then conveyed to an inspection area. Quality checks are performed for coating thickness, appearance, adhesion, and other performance criteria. Automated systems can be integrated for defect detection and sorting.

Technical Specifications

Raymond Electrophoresis Automatic Equipment Production Lines are designed for robust performance and adaptability, with customizable specifications to meet diverse industrial requirements.

| Technical Parameter |

Specification Range |

Notes |

| Production Line Type |

Fully Automatic Gantry, Overhead Conveyor, Dip-Spin |

Configurable for various production layouts and part types. |

| Control System |

Siemens/Mitsubishi PLC, Industrial PC with HMI Touchscreen |

Advanced recipe management, real-time monitoring, fault diagnosis, data logging. |

| Applicable Substrates |

Steel, Galvanized Steel, Aluminum, Magnesium, Cast Iron, Zinc Alloys |

Suitable for most conductive metals. |

| Coating Type |

Cathodic Epoxy E-coat, Cathodic Acrylic E-coat |

Anodic E-coat also available upon request. |

| Coating Thickness |

15 - 35 µm (adjustable) |

Precision control for optimal performance and material efficiency. |

| Paint Utilization Rate |

> 95% |

Achieved through advanced bath management and UF rinsing. |

| Tank Material |

PP, PVC, FRP-lined Steel, Stainless Steel (304/316L) |

Selected for chemical resistance and durability. |

| Curing Oven Temperature |

150 - 220 °C (adjustable) |

High-efficiency ovens with precise temperature uniformity. |

| Environmental Controls |

Integrated Fume Scrubbers, Activated Carbon Adsorption, RO Water Treatment, Wastewater Recycling |

Compliant with international environmental regulations (e.g., EPA, REACH). |

| Energy Efficiency |

High-efficiency Rectifiers, Insulated Tanks, Regenerative Heat Exchangers |

Designed to minimize energy consumption and operational costs. |

| Safety Features |

Emergency Stop Systems, Safety Interlocks, Fire Suppression, Explosion-Proof Components |

Adherence to international safety standards. |

Solving Customer Pain Points

The Raymond Electrophoresis Automatic Equipment Production Line is specifically engineered to address and overcome critical challenges faced by manufacturers in the surface finishing industry.

Challenge: Inconsistent Coating Quality & High Rework Rates

Our Solution: The inherent nature of E-coating ensures uniform film build on all surfaces, including complex internal cavities. Our precise control systems eliminate manual variability, drastically reducing defects, rework, and scrap, leading to consistent, high-quality finishes every time.

Challenge: High Operating Costs & Material Waste

Our Solution: With over 95% paint utilization and advanced ultrafiltration systems that recover unused paint, our lines significantly reduce material consumption. Energy-efficient designs for rectifiers and ovens further lower utility bills, translating to substantial cost savings and a faster ROI.

Challenge: Environmental Compliance & Worker Safety Concerns

Our Solution: Our E-coating lines use water-based, low-VOC paints and integrate comprehensive environmental control systems, including fume extraction, wastewater treatment, and recycling. This ensures compliance with strict regulations and provides a much safer, healthier working environment for your employees.

Challenge: Limited Throughput & Production Bottlenecks

Our Solution: Designed for continuous, automated operation, our lines offer high throughput capabilities. Optimized material handling and process sequencing minimize cycle times, allowing you to meet demanding production schedules and increase overall output without compromising quality.

Challenge: Difficulty Coating Complex & Recessed Parts

Our Solution: Unlike spray painting, E-coating uses electrical current to deposit paint, ensuring complete coverage even in hard-to-reach areas, internal surfaces, and sharp corners. This eliminates the need for manual touch-ups and ensures comprehensive corrosion protection.

Challenge: Lack of Process Control & Traceability

Our Solution: Our advanced PLC and HMI systems provide real-time monitoring and data logging of all critical process parameters. This enables complete traceability for quality assurance audits (e.g., for aerospace or medical clients) and allows for data-driven process optimization.

Related Keywords: Electrophoresis coating line, E-coating production line, electrocoating equipment, automated electrophoretic deposition, industrial e-coat system, cathodic electrocoating, anodic electrocoating, paint electrophoresis, surface treatment automation, corrosion protection coating, high volume e-coating, water-based paint line, automotive e-coat, appliance e-coat, Raymond E-coating.

Electrophoresis automatic equipment production line is a kind of highly automated production line, which is mainly used in electrophoresis coating process, and is widely used in many industries, such as automobile, home appliance, hardware, building materials and so on. The following is a detailed introduction of electrophoresis automatic equipment production line:

I. Definition and Principle

Electrophoresis automatic equipment production line is an automatic production line that deposits paint particles on the surface of the coated object to form a coating under the action of electric field by the principle of electrophoresis. The production line integrates pre-treatment, electrophoretic coating, post-treatment and drying processes, realizing automation and high efficiency of the coating process.

II. Main Components

The electrophoresis automatic equipment production line is mainly composed of the following parts:

| 1. Pre-treatment system: It includes oil removal, rust removal, phosphating and other processes, which is used to remove oil, rust and other impurities on the surface of the coated object and improve the adhesion of the coating. |

| 4. Post-treatment system: including washing, drying and other processes, which is used to remove the residual paint and water on the surface of the coated object and make the coating cured. |

|

| 2. Electrophoresis tank: It is the core equipment of electrophoresis coating, equipped with electrophoresis coating and conductive medium, which makes the coating particles deposited on the surface of coated objects by the action of electric field. |

| 5. Control system: automated control of the whole production line, including setting and monitoring of temperature, time, current and other parameters. |

|

| 3. Ultra-filtration system: it is used to recycle and purify the electrophoretic paint to improve the utilization rate of paint and the quality of coating. |

|

|

|

III. Advantageous features

1. High-efficiency automation: the electrophoresis automatic equipment production line realizes the automation and continuity of the coating process, which greatly improves the production efficiency.

2. High coating quality: by precisely controlling the electrophoresis parameters and process conditions, uniform, dense and strong adhesion coating can be obtained.

3. Environmental protection and energy saving: high utilization rate of electrophoretic coating reduces the generation and emission of waste materials; meanwhile, the drying process adopts high-efficiency energy-saving equipment, which reduces energy consumption.

4. Strong adaptability: the electrophoretic automatic equipment production line can be customized and adjusted according to the needs of different coated objects, and is suitable for coating a variety of materials and shapes.

Why Raymond Electrophoresis automatic Equipment Leads the Industry

Innovative Solutions for Precision, Efficiency & Sustainabilit

1. Advanced Multi-Lane Plating TechnologyRaymond's proprietary multi-lane design can process 6-12 materials simultaneously, increasing throughput by up to 40% compared to single-line systems. Ideal for high volume production in the automotive and renewable energy sectors. |

2. Artificial Intelligence Optimised Process ControlIntegrated Artificial Intelligence algorithms dynamically adjust voltage, temperature and flow rate to ensure ≤2% thickness deviation (military-grade accuracy) while reducing manual intervention by 90%. |

3. Military Specification PlatingPatented multi-stage current control technology ensures ±1.5μm plating consistency in accordance with MIL-STD-753E standards for aerospace and defence applications. |

4. Space-saving modular structureStackable modules reduce the facility footprint by 55% and allow for phased expansion, reducing initial infrastructure costs for small and medium-sized enterprises by 30%. |

5. Closed-loop eco-complianceAutomatic electrophoresis automatic machine line is equipped with specialised exhaust gas treatment plant and wastewater recycling treatment plant with multi-layer filtration to meet different national emission standards. |

6. Cross-industry adaptabilityElectrophoresis automatic machine can be configured into complex geometries (e.g. electric vehicle battery connectors, 5G waveguide components) with material compatibility from 0.1-50mm, serving the semiconductor, marine and hydrogen energy sectors. |

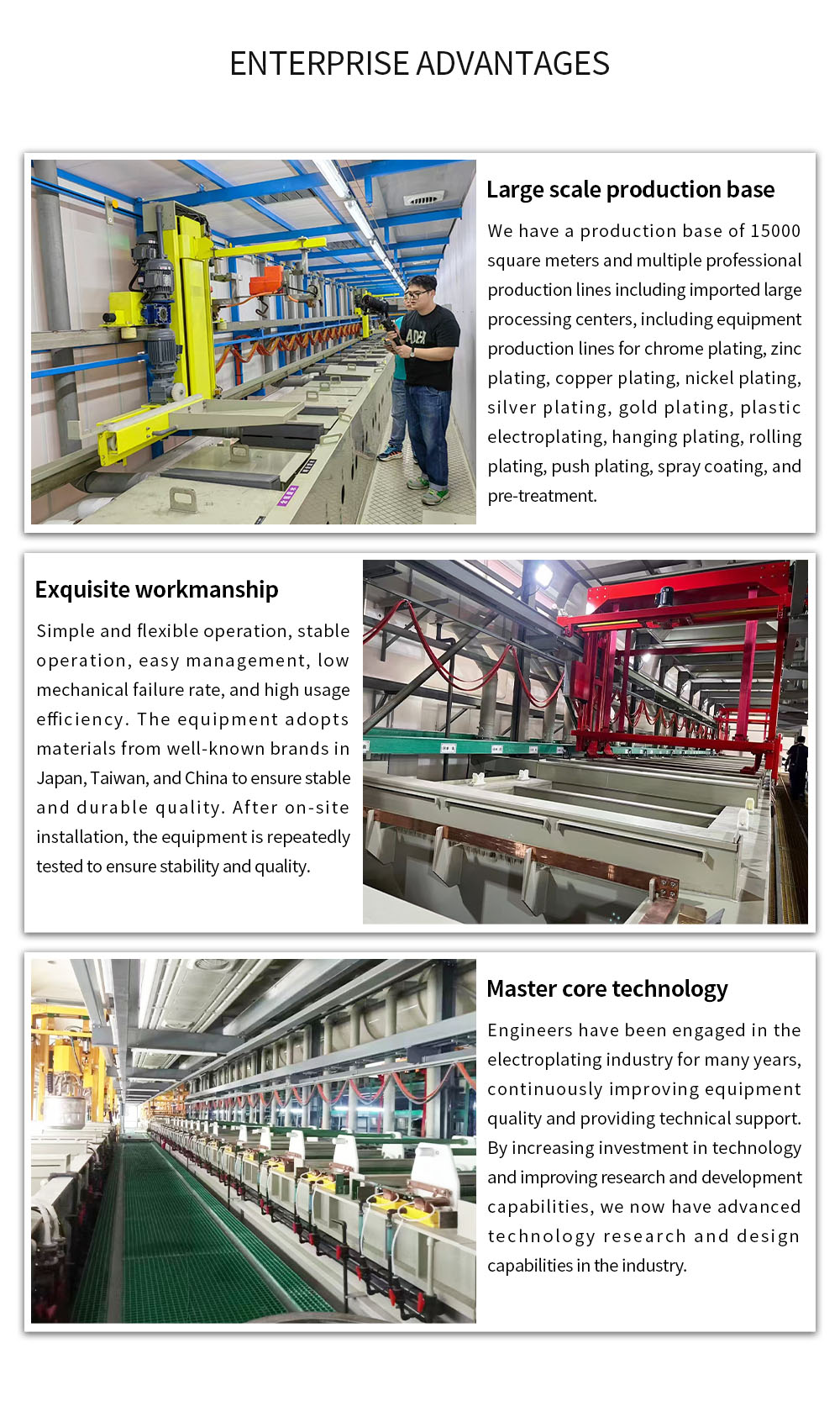

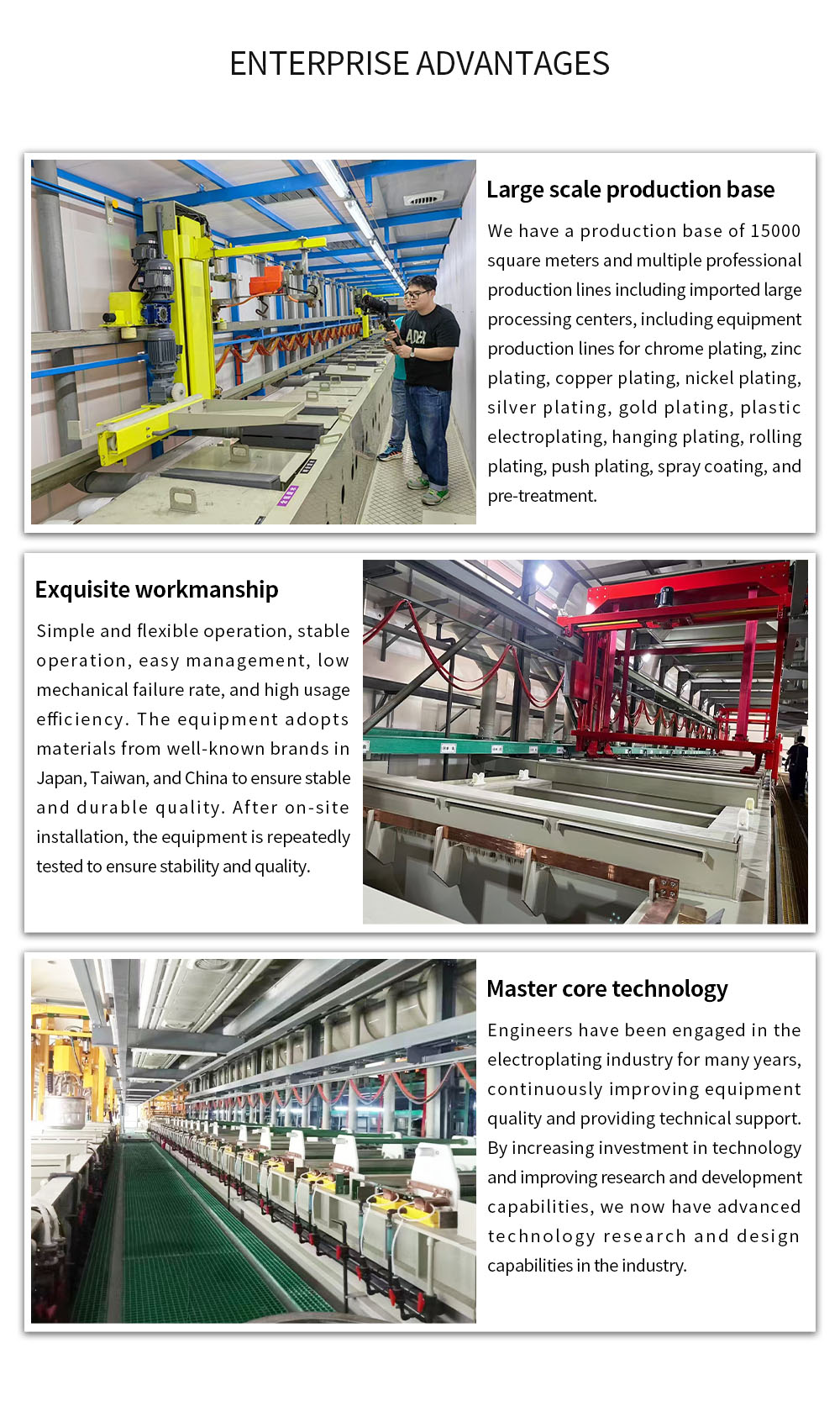

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

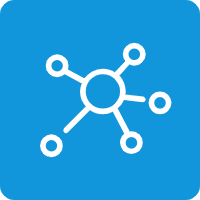

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

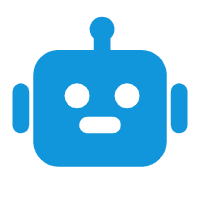

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.