Equipment introduction

Raymond Silver Plating Equipment Production Line - Advanced Surface Finishing Solutions

Raymond Silver Plating Equipment Production Line

Advanced Surface Finishing Solutions · Superior Conductivity · Enhanced Corrosion Resistance · Aesthetic Excellence

Product Introduction

Raymond Silver Plating Equipment Production Line is a state-of-the-art solution engineered for precision and performance in surface finishing. It integrates advanced automation, intelligent control systems, and flexible process capabilities to deliver high-quality silver coatings. These coatings are renowned for their exceptional electrical conductivity, superior corrosion resistance, and brilliant aesthetic appeal, making them indispensable across diverse industries such as electronics, automotive, jewelry, and medical devices.

At Raymond, we understand that silver plating is not just about aesthetics; it's about enhancing critical product functionalities. Our production lines are meticulously designed to optimize efficiency, minimize operational costs, and ensure strict environmental compliance. We provide comprehensive, tailored solutions that meet the most demanding specifications, ensuring consistent, reliable, and high-performance silver plating for every application.

Core Advantages of Raymond Silver Plating Lines

- Unmatched Electrical Conductivity: Silver boasts the highest electrical conductivity among all metals, making our plating lines ideal for critical electronic components, connectors, and busbars where signal integrity and minimal resistance are paramount.

- Exceptional Corrosion and Oxidation Resistance: Our silver coatings provide a robust barrier against environmental degradation, significantly extending the lifespan and reliability of plated parts, even in harsh conditions.

- Superior Aesthetic Finish: Achieve brilliant, uniform, and highly reflective silver finishes that enhance the visual appeal and market value of your products, particularly in decorative and luxury applications.

- Optimized Production Efficiency: Featuring advanced automation and streamlined process flows, our lines minimize manual intervention, reduce cycle times, and maximize throughput, leading to significant productivity gains and a faster return on investment.

- Reduced Operational Costs: Through energy-efficient designs, precise chemical dosing, and minimized waste generation, Raymond silver plating lines contribute to substantial reductions in labor, energy, and raw material expenses.

- Consistent and High-Quality Coatings: Intelligent monitoring and precise parameter control ensure uniform coating thickness, excellent adhesion, and consistent quality across all batches, meeting the most stringent industry standards.

- Environmental Responsibility: Designed with sustainability at its core, our lines incorporate advanced wastewater treatment and exhaust gas management systems, ensuring compliance with global environmental regulations and promoting eco-friendly manufacturing.

Process Flow

The Raymond Silver Plating Equipment Production Line employs a sophisticated, multi-stage process flow to ensure the deposition of a uniform, dense, and highly adherent silver layer. Each step is precisely controlled to achieve optimal coating performance and durability.

1

Pre-treatment & Cleaning

Workpieces undergo thorough cleaning, including degreasing, rinsing, and acid activation, to remove contaminants and prepare the surface for optimal silver adhesion. This crucial step ensures a pristine substrate for plating.

2

Silver Electroplating

Parts are immersed in a precisely formulated silver electrolyte solution. A controlled DC current is applied, facilitating the uniform deposition of silver ions onto the workpiece surface. Parameters like current density, temperature, and pH are meticulously maintained.

3

Post-Plating Treatments

Following electroplating, workpieces undergo multi-stage rinsing to remove residual chemicals. This is often followed by anti-tarnish treatments or passivation to enhance corrosion resistance and maintain the silver's luster.

4

Drying & Inspection

Finally, parts are thoroughly dried using heated air or other methods. A comprehensive inspection ensures the silver coating meets all quality specifications for thickness, adhesion, appearance, and performance.

Process Innovation

Our lines feature advanced rectifier technology for ultra-precise current control, ensuring uniform silver deposition even on complex geometries and high-aspect ratio parts. Automated material handling systems minimize human contact, reducing contamination risks and enhancing operational safety. We also integrate closed-loop rinsing and chemical recovery systems to significantly reduce water consumption and waste generation, aligning with sustainable manufacturing practices.

Technical Specifications

Raymond Silver Plating Equipment Production Lines are designed for adaptability and high performance, offering a range of configurations to suit diverse production requirements. Below are typical technical specifications, which can be fully customized to meet your specific operational needs and industry standards:

| Technical Parameter |

Specification Range |

Notes |

| Production Line Type |

Fully Automatic Gantry, Semi-Automatic, Manual (Rack & Barrel Plating) |

Customizable based on automation level and part geometry |

| Applicable Substrates |

Copper, Brass, Steel, Stainless Steel, Aluminum (with pre-treatment), various alloys |

Designed for diverse metallic and some non-metallic substrates |

| Coating Thickness |

0.0001-0.001 inches (2.5-25 µm) |

Meets international standards like ASTM B700, QQ-S-365, AMS 2410 |

| Silver Purity |

99.0% - 99.99% |

Ensures maximum conductivity and performance for specific applications |

| Plating Speed |

Adjustable based on current density, bath chemistry, and desired thickness |

Optimized for throughput and coating quality |

| Production Capacity |

Customizable based on tank volume, rectifier capacity, and process speed |

Scalable for small batch to high-volume continuous production |

| Automation Level |

PLC-controlled, HMI touch screen, real-time monitoring, data logging |

Minimizes human error, enhances process stability and traceability |

| Tank Material |

PP/PVC/FRP lined steel, Stainless Steel |

Ensures durability and chemical resistance to silver plating solutions |

| Energy Efficiency |

High-efficiency rectifiers, optimized heating/cooling, intelligent power management |

Reduces operational energy consumption and carbon footprint |

| Environmental Controls |

Integrated exhaust gas scrubbers, advanced wastewater treatment, chemical recovery systems |

Ensures compliance with stringent environmental regulations |

Customized Services

At Raymond, we specialize in delivering bespoke silver plating solutions that perfectly align with your unique manufacturing requirements. Our dedicated team of experts provides end-to-end support, from initial consultation and detailed engineering design to precision equipment manufacturing, seamless installation, and comprehensive post-sales technical support. We ensure that every Raymond Silver Plating Equipment Production Line is meticulously tailored to your specific production goals, facility layout, and long-term strategic objectives, providing a truly integrated and optimized solution for unparalleled performance.

Solving Customer Pain Points

The Raymond Silver Plating Equipment Production Line is meticulously engineered to address and overcome the most critical challenges faced by manufacturers in the metal finishing industry, transforming common pain points into significant competitive advantages:

Addressing Conductivity Demands

Our lines ensure the highest electrical conductivity for components, crucial for high-performance electronics and electrical systems, preventing signal loss and improving overall device efficiency and reliability.

Combating Corrosion and Tarnishing

Silver coatings provide an exceptional barrier against oxidation and various corrosive agents, significantly extending the lifespan of components and maintaining their functional and aesthetic integrity over time.

Ensuring Uniformity on Complex Geometries

Advanced process control, innovative rack and barrel designs, and precise current distribution ensure uniform silver deposition even on intricate parts, eliminating inconsistencies and drastically reducing rework rates.

Optimizing Production Efficiency and Throughput

Highly automated systems and optimized process flows dramatically increase processing speed and capacity, leading to higher output, shorter lead times, and substantial improvements in overall productivity and profitability.

Minimizing Operational Costs and Waste

Raymond lines are designed for maximum resource efficiency, reducing energy consumption, chemical usage, and material waste. This translates to significant savings in operational expenses and a quicker return on investment, while promoting sustainable practices.

Meeting Stringent Quality Standards

Precise control of all plating parameters and robust quality assurance processes ensure that every silver-plated product meets the highest industry standards for adhesion, purity, thickness, and finish, guaranteeing consistent excellence.

Customer Success Stories

Our clients consistently achieve remarkable results after implementing Raymond Silver Plating Equipment Production Lines. A leading aerospace component manufacturer reported a **45% increase in the lifespan of their silver-plated connectors** due to enhanced corrosion resistance and improved conductivity. A prominent jewelry producer experienced a **60% reduction in rework and polishing time** thanks to the superior uniformity and aesthetic quality of our plating. Furthermore, an electronics firm noted a **25% decrease in material consumption** and a **35% improvement in overall production throughput**, directly attributing these gains to the efficiency and precision of our automated silver plating lines. These successes highlight our commitment to delivering tangible value and fostering long-term partnerships.

Related Keywords: silver plating equipment production line, silver electroplating, silver coating, surface finishing, high conductivity, corrosion resistance, anti-tarnish, automated plating, industrial silver plating, precision plating, functional plating, decorative plating, environmental compliance, customized solutions, Raymond

Silver Plating Equipment Line is a production line dedicated to the silver plating process that integrates several process steps and equipment for efficient silver plating production. Below are some details about the silver plating equipment production line:

I. Line Overview

A silver plating equipment production line usually consists of multiple process segments such as pretreatment, silver plating, and post-treatment, each of which is equipped with appropriate equipment and tools. The production line is designed to realize automatic, continuous and efficient production to meet the large-scale silver plating demand.

II. Main Equipment

| 1. Pre-treatment equipments: including equipments required for oil removal, rust removal, activation and other processes, such as ultrasonic cleaning machine, pickling tank and so on. These equipments are used to remove the oil, rust and other impurities on the surface of the parts to be plated, in order to improve the adhesion and aesthetics of the silver-plated layer. |

|

| 2. Silver plating tank: Silver plating tank is the core equipment of silver plating equipment production line, which is used to deposit the silver layer on the surface of the parts to be plated. The silver plating tank usually adopts electroplating method to reduce the silver ions to metallic silver on the surface of the parts to be plated through electrolysis. |

|

| 3. Post-treatment equipment: This includes equipment required for cleaning, drying, polishing and other processes. These equipments are used to remove the residual electrolyte and other impurities after silver plating, so as to make the surface of silver plated parts more smooth and beautiful. |

|

Why Raymond Silver Plating Equipment Leads the Industry

Innovative Solutions for Precision, Efficiency & Sustainabilit

1. Advanced Multi-Lane Plating TechnologyRaymond's proprietary multi-lane design can process 6-12 materials simultaneously, increasing throughput by up to 40% compared to single-line systems. Ideal for high volume production in the automotive and renewable energy sectors. |

2. Artificial Intelligence Optimised Process ControlIntegrated Artificial Intelligence algorithms dynamically adjust voltage, temperature and flow rate to ensure ≤2% thickness deviation (military-grade accuracy) while reducing manual intervention by 90%. |

3. Military Specification PlatingPatented multi-stage current control technology ensures ±1.5μm plating consistency in accordance with MIL-STD-753E standards for aerospace and defence applications. |

4. Space-saving modular structureStackable modules reduce the facility footprint by 55% and allow for phased expansion, reducing initial infrastructure costs for small and medium-sized enterprises by 30%. |

5. Closed-loop eco-complianceAutomatic silver machine line is equipped with specialised exhaust gas treatment plant and wastewater recycling treatment plant with multi-layer filtration to meet different national emission standards. |

6. Cross-industry adaptabilitySilver plating machine can be configured into complex geometries (e.g. electric vehicle battery connectors, 5G waveguide components) with material compatibility from 0.1-50mm, serving the semiconductor, marine and hydrogen energy sectors. |

III. Process characteristics

1. High degree of automation: silver plating equipment production line is usually equipped with automatic control system, which can realize automatic loading, automatic silver plating, automatic discharging and other processes, greatly reducing the difficulty of manual operation and labor intensity.

2. High production efficiency: the production line adopts continuous production mode, which can deal with several pieces to be plated at the same time, greatly improving the production efficiency.

3. Stable quality of plating layer: through precise control of various parameters in the process of silver plating, such as current density, temperature of plating solution, composition of plating solution, etc., the quality of silver plating layer can be ensured to be stable and reliable.

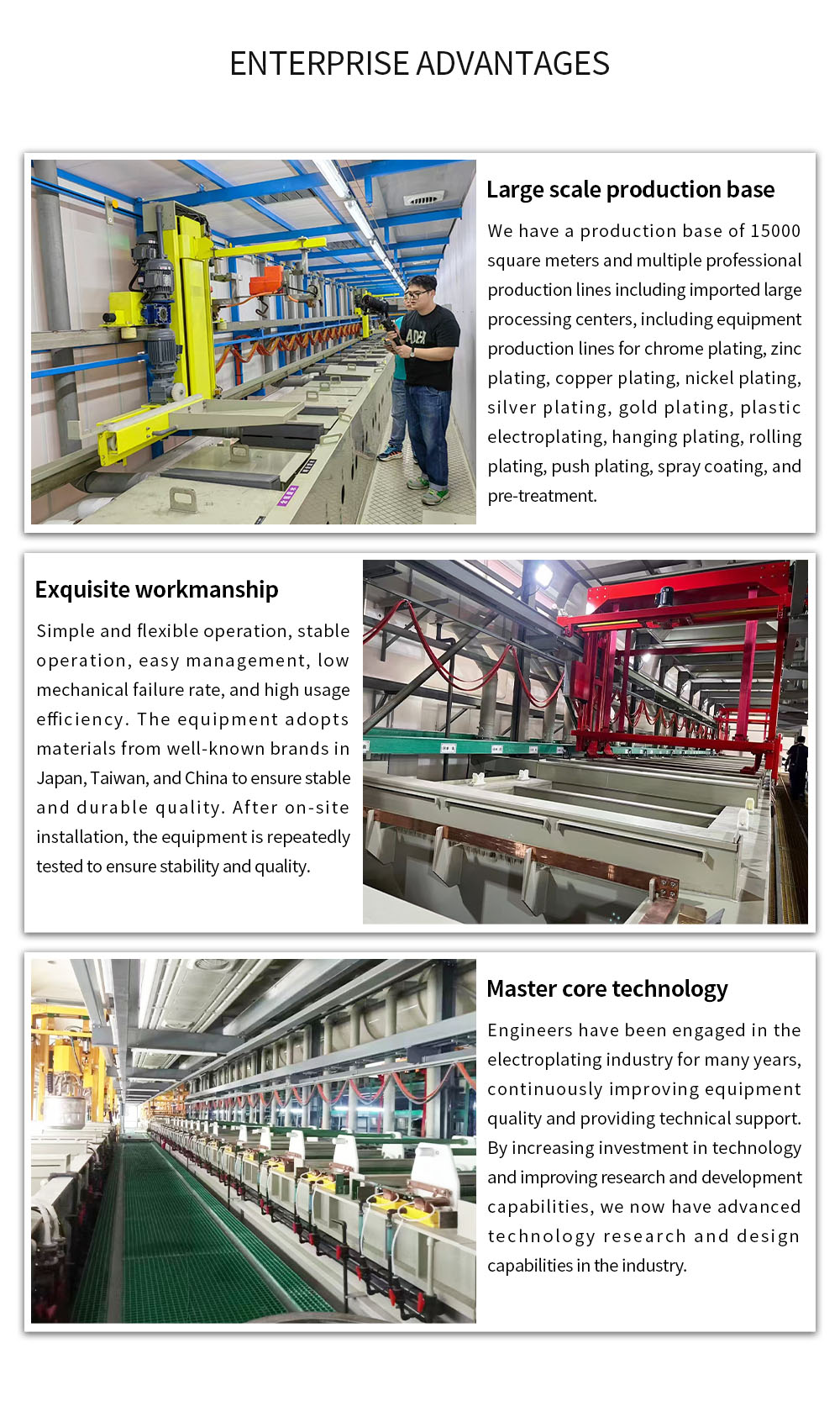

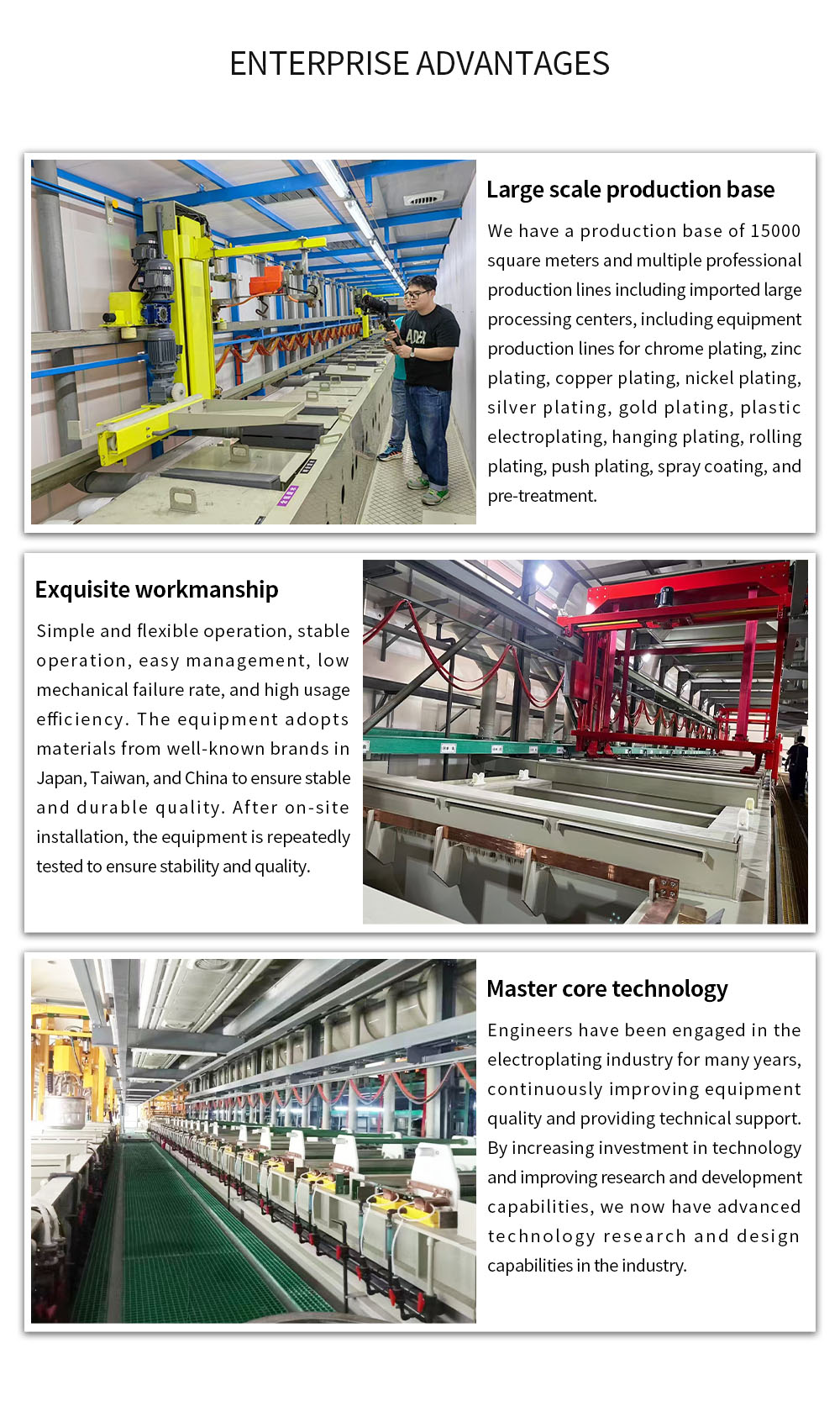

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

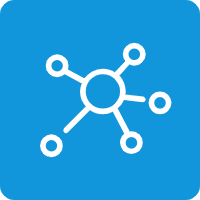

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.