Equipment introduction

Raymond Copper Plating Equipment Production Line - Professional Electroplating Solutions

Raymond Copper Plating Equipment Production Line

Professional Electroplating Solutions · Cost Reduction · Efficiency Enhancement · Fault Minimization

Product Introduction

Raymond Copper Plating Equipment Production Line is a high-efficiency, high-precision electroplating solution designed specifically for modern industrial needs. This production line integrates advanced automation technology and flexible process flows, aiming to provide customers with excellent plating quality, significant improvements in production efficiency, and reliable operational stability.

Whether it's mass production of large workpieces or fine plating of precision components, Raymond Copper Plating Equipment Production Line can provide customized solutions to meet the stringent requirements of various industries and application scenarios. We deeply understand the critical impact of electroplating processes on product performance and cost, therefore from the initial design, we fully considered how to help customers solve practical pain points.

Core Advantages

- Reduced Operating Costs: Significantly lower labor and production costs by optimizing energy consumption, reducing material waste, and increasing automation levels

- Improved Production Efficiency: Automated control systems and flexible process flows shorten production cycles and greatly increase capacity

- Reduced Failure Rate and Maintenance: Adopting high-quality materials and exquisite manufacturing processes ensures stable equipment operation and reduces the incidence of failures

- Enhanced Product Quality: Precise control of process parameters and uniform plating layer formation technology ensure that every product meets high-standard quality requirements

- Environmental Protection and Sustainable Development: Optimized wastewater treatment and exhaust gas emissions comply with the strictest environmental standards, helping enterprises achieve green production

Process Flow

Raymond Copper Plating Equipment Production Line utilizes advanced electrochemical principles, forming a uniform, dense, and strongly adhesive copper plating layer on the workpiece surface through a series of precisely controlled steps. Our process flow is meticulously designed and optimized to ensure optimal results at every stage.

1

Loading and Pre-treatment

Workpieces enter the production line through an automated loading system, undergoing degreasing, rinsing, micro-etching, and pickling to ensure surface cleanliness.

2

Copper Plating

Using advanced pressurized nozzle spray design, copper ions are reduced and deposited on the workpiece surface under direct current, forming a uniform plating layer.

3

Rinsing and Post-treatment

Multi-stage rinsing removes residual plating solution, followed by pickling, tin plating and other post-treatment steps to optimize plating layer performance.

4

Automated Control

Intelligent PLC touchscreen system provides precise control and real-time monitoring, automatically adjusting key parameters to ensure process stability.

Process Features

We adopt an advanced pressurized nozzle spray design to ensure that the plating solution uniformly and fully covers the workpiece surface, especially for complex shapes or workpieces with micro-holes, achieving excellent through-hole effects. The production line can support high current density production (20-25 ASF) as needed to improve efficiency. The entire electroplating process is precisely controlled and real-time monitored by an intelligent PLC touchscreen system, greatly reducing the need for manual intervention.

Technical Specifications

Raymond Copper Plating Equipment Production Line can be highly customized according to specific customer needs. We offer a full range of solutions from small laboratory equipment to large industrial production lines. The following are typical technical specification parameter ranges:

| Technical Parameter |

Specification Range |

Notes |

| Production Line Type |

Fully automatic gantry straight-line electroplating production line, semi-automatic production line, manual production line |

Customizable |

| Applicable Plating Types |

Copper, zinc, nickel, hard chrome, decorative chrome, chemical phosphating and others |

Can also plate copper and tin |

| Automation Level |

PLC touchscreen control, open program, high automation |

Precise positioning |

| Structural Design |

Reasonable, compact, stable |

Customizable dimensions based on site and process requirements |

| Traveling System |

Single-hook or double-hook design |

Stable operation, precise positioning, programmable control |

| Plating Tank Material |

PP+SUS304# |

Customizable dimensions, configurable with cathode and anode shielding |

| Current Density |

20-25 ASF |

Adjustable according to process requirements |

| Production Capacity |

1500-2000㎡ (typical configuration) |

Customizable according to customer output requirements |

| Design Load Factor |

≥85% |

Typical value for semi-automatic production lines |

| Safety Features |

Complies with safety production industry standards |

Equipped with harmful substance emission control measures |

Customized Services

We deeply understand that each customer's needs are unique, therefore we provide comprehensive customized services. From initial requirement analysis and scheme design, to equipment manufacturing, installation and commissioning, and after-sales service and technical support, our professional team will provide you with one-stop solutions throughout the entire process. Regardless of your production scale or how special your process requirements are, we can customize the most suitable copper plating equipment production line for you.

Solving Customer Pain Points

Raymond Copper Plating Equipment Production Line is dedicated to solving core pain points in electroplating production for customers, helping enterprises achieve sustainable development and enhance market competitiveness. We deeply understand industry challenges and provide targeted solutions:

Significantly Reduced Production Costs

By automating and reducing labor input, optimizing plating solution consumption, and lowering scrap rates, overall production costs are substantially cut. Precise parameter control and efficient plating layer formation reduce rework and material waste.

Greatly Improved Production Efficiency

Fully automated production processes and flexible process switching capabilities significantly shorten production cycles and greatly increase output per unit time. This is crucial for meeting rapidly growing market demands.

Effectively Reduced Equipment Failures and Maintenance

Adopting internationally renowned brand components and strict quality control standards ensures stable and reliable equipment operation. Modular design and intelligent diagnostic systems make daily maintenance more convenient.

Continuously Enhanced Product Quality

Precise control of current density, temperature, and pH value, combined with advanced nozzle design, ensures uniform, dense, and strongly adhesive plating layers, meeting the highest standards of product quality.

Achieving Green and Environmentally Friendly Production

We prioritize environmental protection, and our equipment design complies with the latest environmental regulations. Through optimized wastewater and exhaust gas treatment systems, we help customers achieve clean production and reduce environmental risks.

Providing Customized Solutions

We offer comprehensive customized solutions from scheme design, equipment manufacturing, installation and commissioning, to after-sales service, ensuring that the production line perfectly matches the customer's production process and capacity goals.

Customer Success Stories

We have provided successful solutions for numerous customers, helping them achieve significant improvements in production efficiency and substantial cost reductions. Through our copper plating equipment production lines, customers can typically achieve: 30-50% improvement in production efficiency, 20-35% reduction in production costs, over 60% reduction in equipment failure rates, and product quality compliance rates exceeding 99%.

Related Keywords: copper plating equipment production line, copper plating equipment, electroplating production line, automated electroplating equipment, gantry electroplating line, barrel plating line, rack plating line, electroplating process, copper plating technology, surface treatment equipment, electroplating solutions, cost reduction, efficiency improvement, fault reduction, environmentally friendly electroplating, customized electroplating equipment, Raymond

Copper plating equipment production line is a series of equipment used for copper plating on the surface of the substrate, widely used in electronics, automotive, construction, hardware and other industries. The following is a detailed introduction about copper plating equipment production line:

I. Production line composition

| 1. pre-treatment equipment: including cleaning, degreasing, descaling and other devices, used to remove the dirt and oxidized layer on the surface of the substrate, to ensure a good combination of plating and substrate. |

| 4. control system: used to monitor and adjust various parameters in the copper plating process, such as current, voltage, plating solution temperature, plating solution composition, etc., to ensure the stability and consistency of the plating quality. |

|

| 2. copper plating tank: is the core equipment of the copper plating process, usually using electrolysis to reduce copper ions into copper metal and deposited on the surface of the substrate. The design of copper plating tank needs to consider factors such as current distribution uniformity, temperature control of plating solution, and circulation of plating solution. |

| 5. Auxiliary equipments: including traveling car, crane, conveyor belt, etc., used for lifting, transporting, loading and unloading of base material. |

|

| 3. post-treatment equipment: including cleaning, drying, polishing and other devices, used to remove residual plating solution and impurities on the surface of the plating layer, to improve the finish and corrosion resistance of the coating. |

|

|

|

Why Raymond Copper Plating Equipment Leads the Industry

Innovative Solutions for Precision, Efficiency & Sustainabilit

1. Advanced Multi-Lane Plating TechnologyRaymond's proprietary multi-lane design can process 6-12 materials simultaneously, increasing throughput by up to 40% compared to single-line systems. Ideal for high volume production in the automotive and renewable energy sectors. |

2. Artificial Intelligence Optimised Process ControlIntegrated Artificial Intelligence algorithms dynamically adjust voltage, temperature and flow rate to ensure ≤2% thickness deviation (military-grade accuracy) while reducing manual intervention by 90%. |

3. Military Specification PlatingPatented multi-stage current control technology ensures ±1.5μm plating consistency in accordance with MIL-STD-753E standards for aerospace and defence applications. |

4. Space-saving modular structureStackable modules reduce the facility footprint by 55% and allow for phased expansion, reducing initial infrastructure costs for small and medium-sized enterprises by 30%. |

5. Closed-loop eco-complianceAutomatic copper plating machine line is equipped with specialised exhaust gas treatment plant and wastewater recycling treatment plant with multi-layer filtration to meet different national emission standards. |

6. Cross-industry adaptabilityCopper plating machine can be configured into complex geometries (e.g. electric vehicle battery connectors, 5G waveguide components) with material compatibility from 0.1-50mm, serving the semiconductor, marine and hydrogen energy sectors.

|

II. Working Principle

The working principle of copper plating equipment production line is based on electrolysis principle. In the copper plating tank, the substrate serves as the cathode and the copper plate or ball serves as the anode, and the two are connected through the electrolyte (solution containing copper ions). Under the action of direct current, copper ions dissolve from the anode and migrate to the surface of the cathode, and are reduced to metallic copper and deposited on the substrate, forming a uniform layer of copper plating.

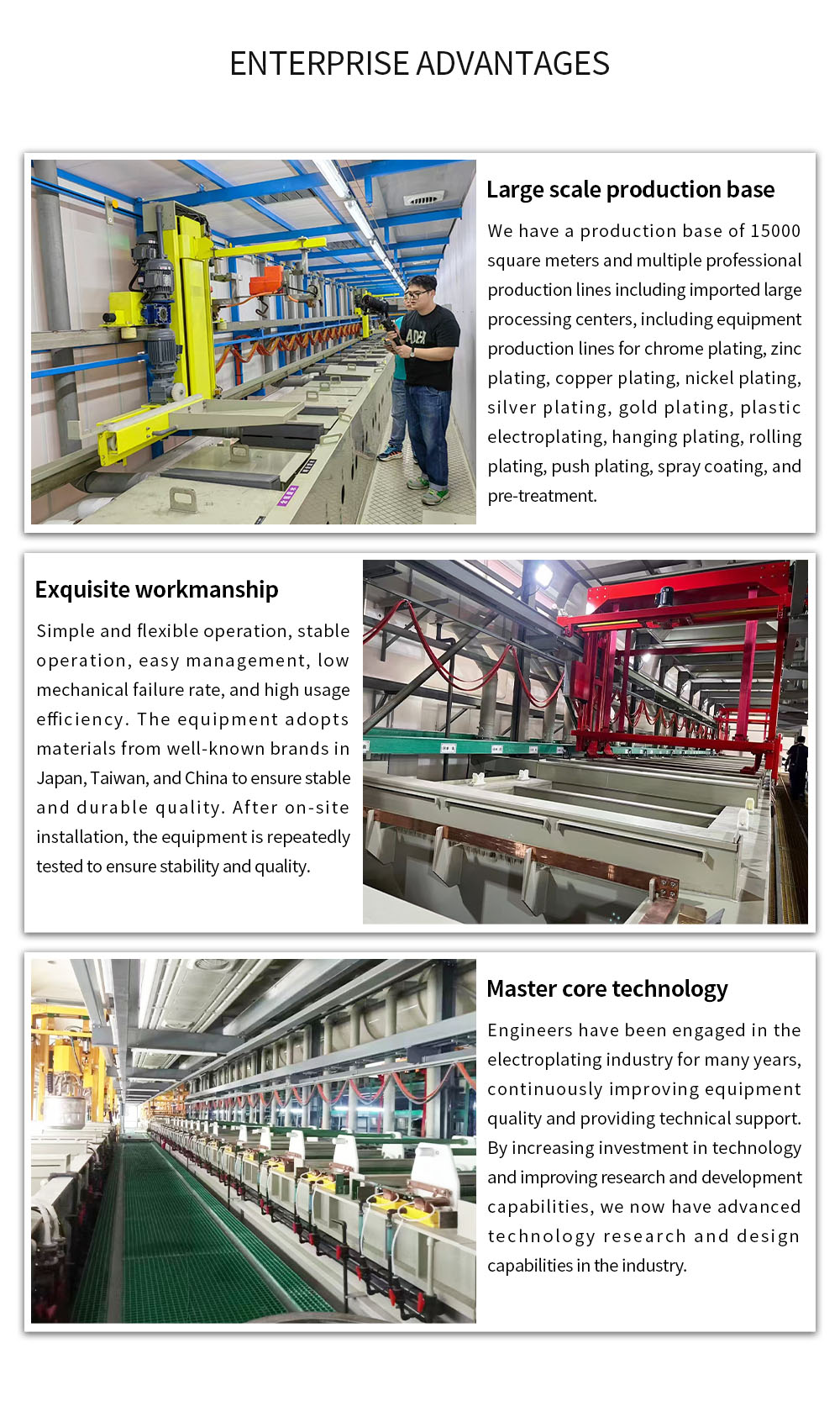

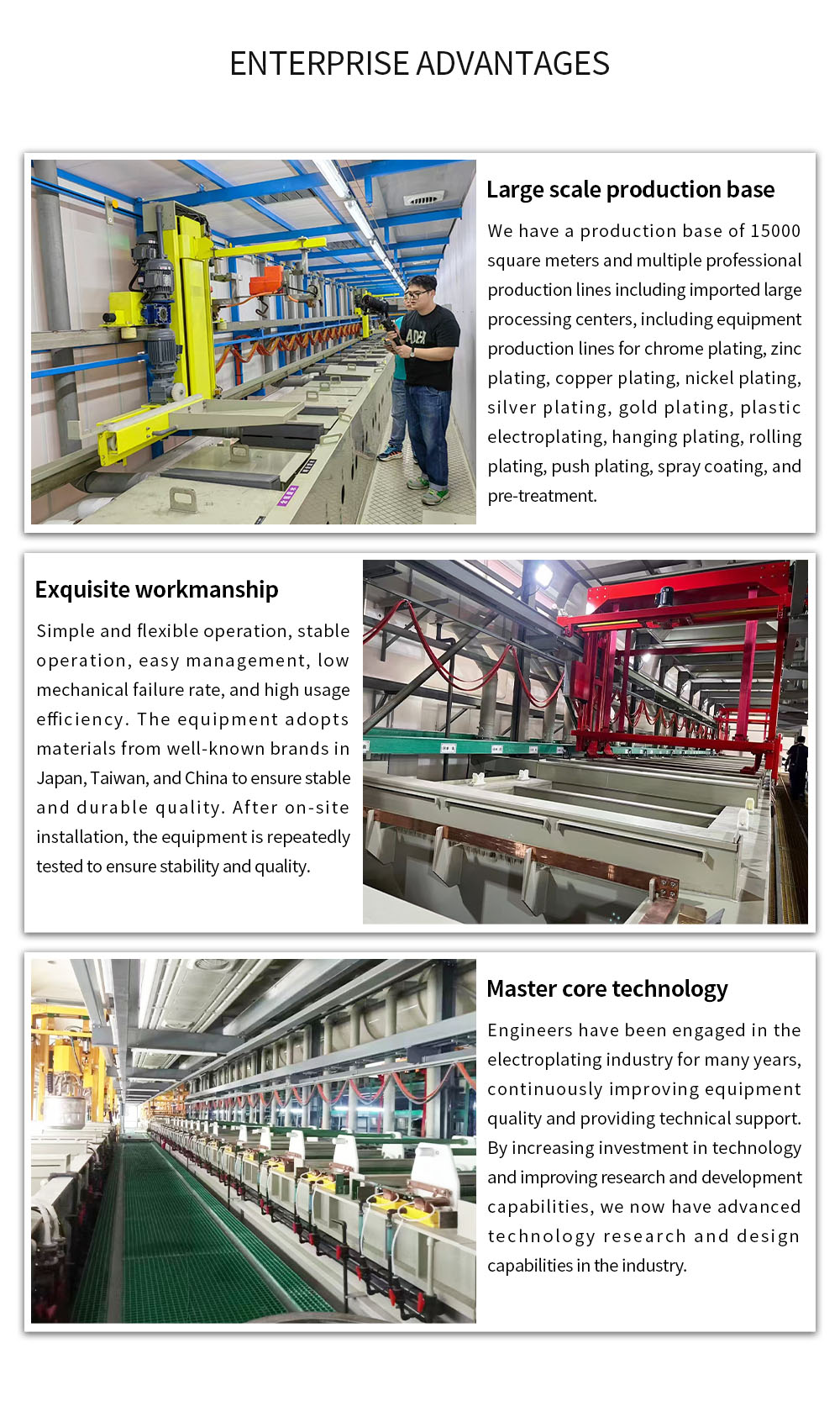

Large scale production base

Lei Meng Equipment have a production base of 15000square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

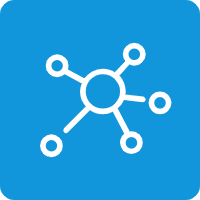

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan, and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

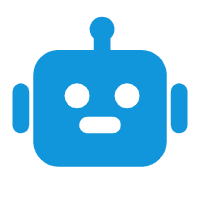

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000square meters. lt has multiple professional production lines, including imported large-scale machining centers.